Join our e-newsletter

Register for our company e-newsletter and stay up-to-date with everything happening at Biosol.

Biosol treats the cause of sewer odour and corrosion.

Biosol removes the biofilm / sediment layer in the base of the sewer pipes where sewer odour is produced.

Without sewer odour, biogenic corrosion will not occur.

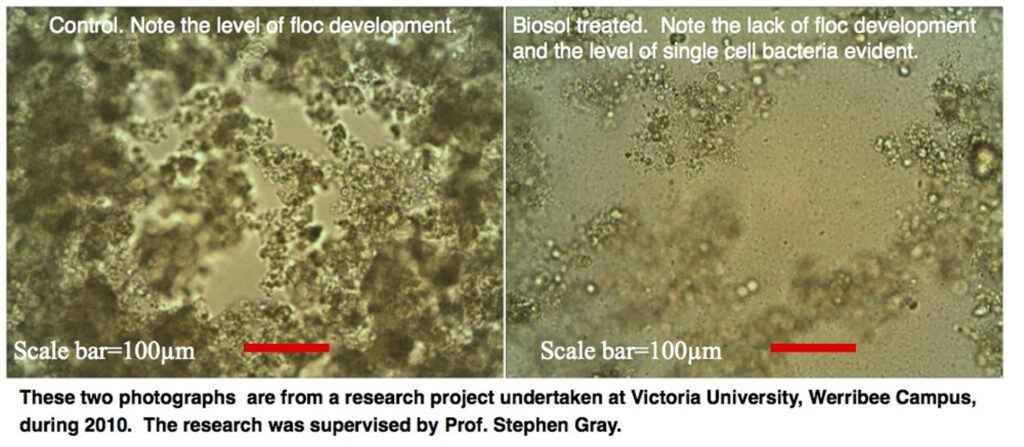

Field evidence and research funded by KBR and undertaken at Victoria University, supervised by Professor Stephen Gray, shows that Biosol changes the bacteria from a floc (biofilm) form to a single cell form. Biosol technology blocks communication signals between the bacteria and they revert to a single cell form.

Bacterial in a single cell form cannot produce odour or the glues (exopolysaccharides) required to form biofilms or stick to the sewer pipes. The slimes layer dislodges and flows to the sewerage treatment plant for process. This minimises odour and corrosion within the sewer. Biosol doesn’t kill bacteria, so microbial resistance will not occur.

This process of changing the bacterial state is controlled by manipulating the dosing levels of Biosol.

Burdekin Shire Council, Ayr End of the SPS 5 pressure main.

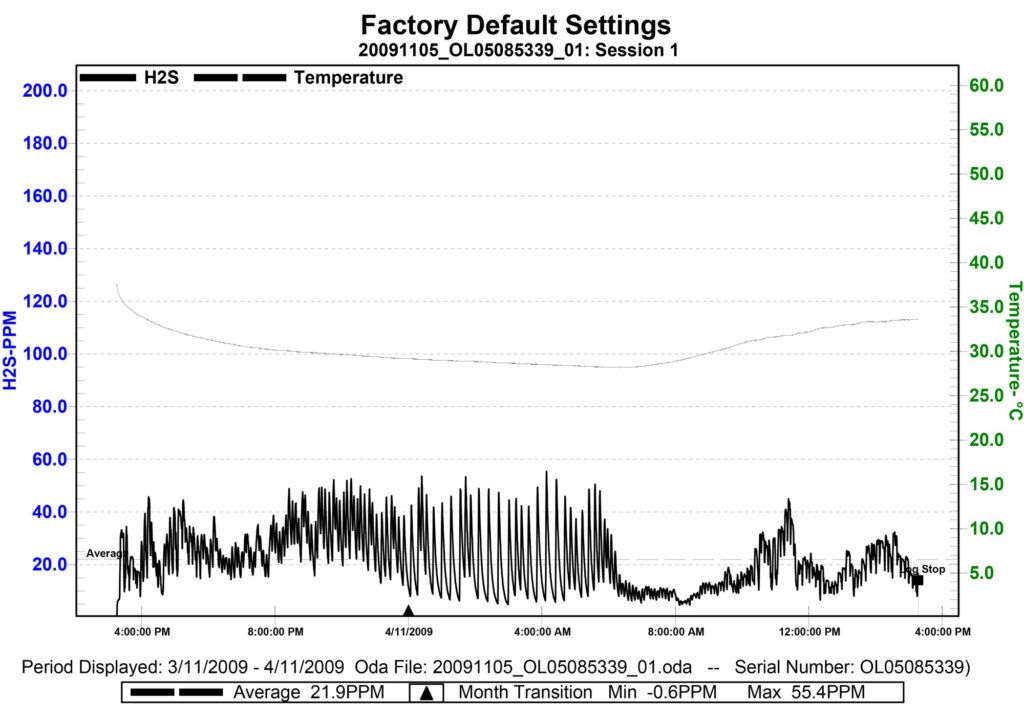

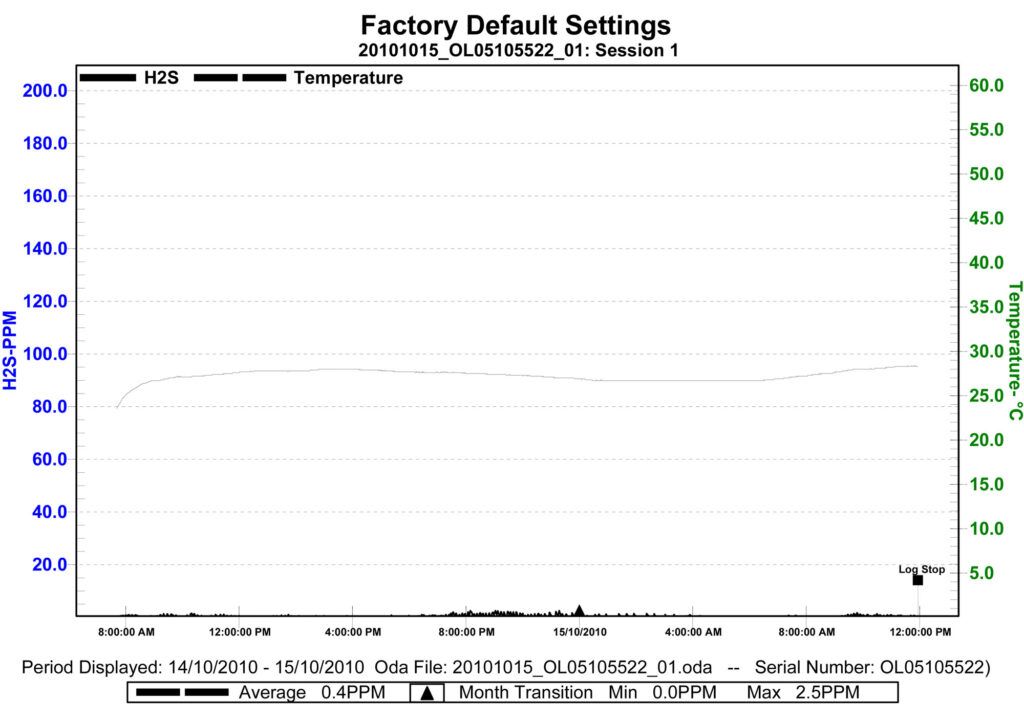

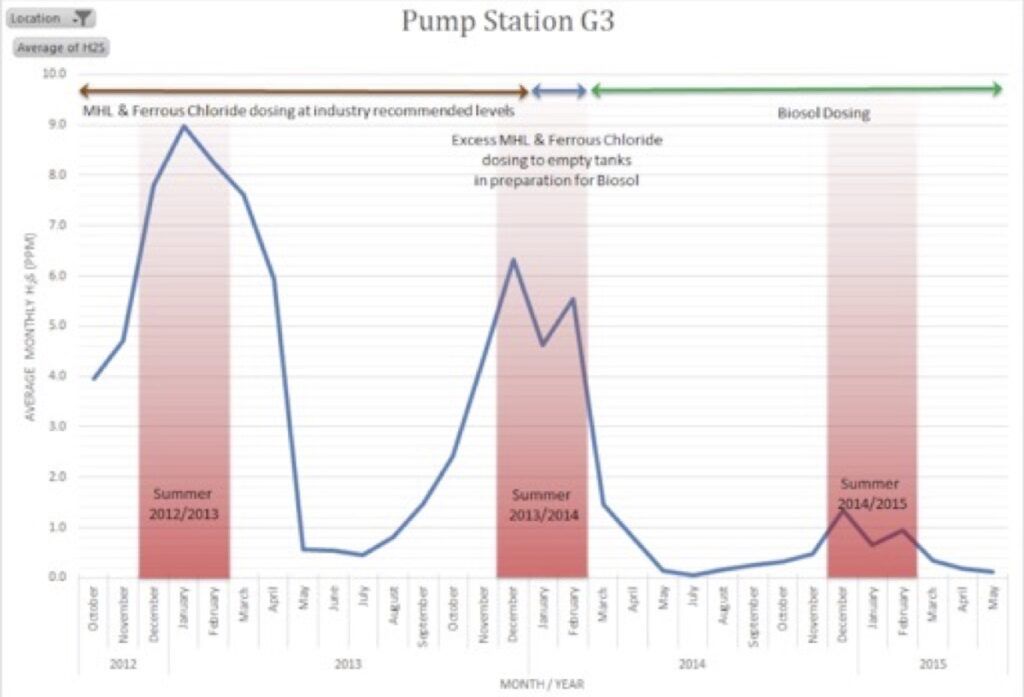

After one year, Biosol had removed the Biofilm / sediment in the sewer pipe almost eliminating sewer odour.

At the end of the SPS 5 pressure main, the wet well surface pH before Biosol dosing measured at 0.5. Within 3 years of Biosol dosing, the surface pH had risen to pH 3.5. This represents a substantial decrease in the rate of corrosion of the wet well.

“IMPROVED ODOUR CONTROL: A CASE STUDY USING BIOSOL IN GRIFFITH NSW”

Presented by Nick Chandler, at the “Australian Water Association, QWater Conference 24 – 25 November 2016”

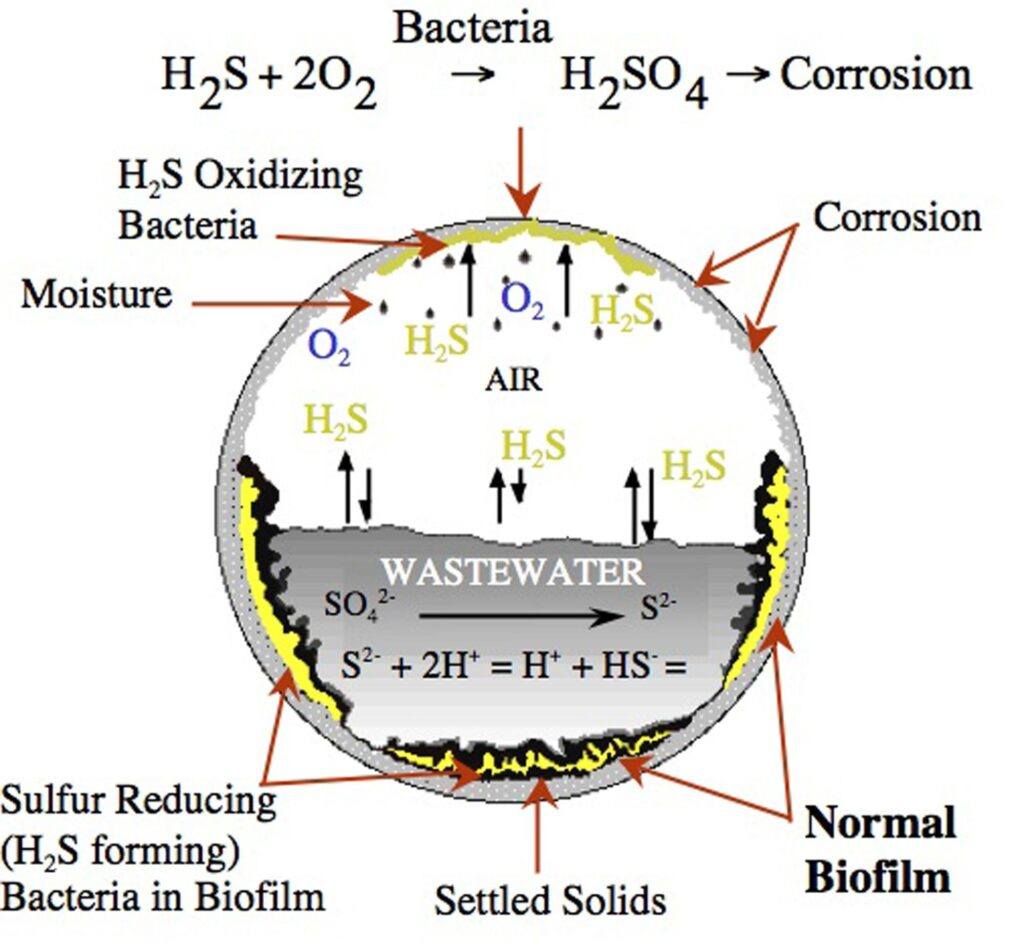

Sewer odour is often referred to as rotten egg gas, which is a major cause of odour complaints.

This odour is produced by anaerobic Sulphate Reducing Bacteria (SRB) within the biofilm/sediment layer (slime) in the invert of the sewer. The SRB can only make odour in the slime layer when they communicate with one another, which they do by trace levels of chemical cell signals.

Biosol blocks the communication signals which bacteria use to form and maintain the slimes layer. The slimes layer disintegrates removing the cause of sewer odour and corrosion

Sulfur Reducing Bacteria (SRB) can only produce odour (H2S) in the biofilm/settled solids layer at the base of the sewer.

Biosol removes the biofilm/settled solids and prevents the sewage generating odour and causing corrosion.

You can measure the effectiveness of Biosol dosing using OdaLog or similar instruments. Biosol can assist you by compiling the OdaLog data outputs into week by week or month by month graphs for presentation at meetings or to your superiors.

Sewers are often out of sight and out of mind. This can lead to very expensive repair, or even catastrophic sewer failure.

Sewer corrosion is caused by sulphuric acid (H2SO4) which is formed from the oxidation of hydrogen sulphide gas (H2S). Sulphuric acid causes significant and costly damage to sewer infrastructure, including concrete and AC pipes, pump stations, manholes and electrical components.

Within Australia, the cost of asset degradation due to sulphide-induced corrosion is estimated at around $100 million per year.

Sulphuric acid is what caused this corrosion down to the reinforcing bars.

Without sewer odour (H2S gas) you cannot get biogenic sulphuric acid (H2SO4) corrosion.

Biosol’s sulphide management solution removes the biofilm / sediment layer (slimes) where odour is produced. This prevents corrosion of infrastructure from Sulphuric acid production.

With your assistance, our team at Biosol can measure the anticipated rate of corrosion of wet wells and discharge manholes. The team do this by measuring the surface pH of the infrastructure. A pH 2 (acidic) will corrode 50mm of sacrificial concrete in 8 years, whereas at pH 4 will take 100 years to corrode the same 50mm of concrete (Los Angeles Sanitary District Research).

Biosol dosing is designed to increase pH values from < 2 to > 4 to minimise the acidic, corrosive conditions and substantially increase asset life.